Welcome To Swift Technoplast

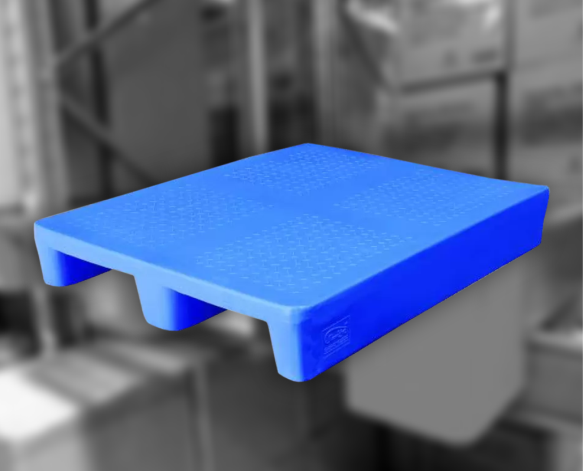

India’s Premium

Brand For

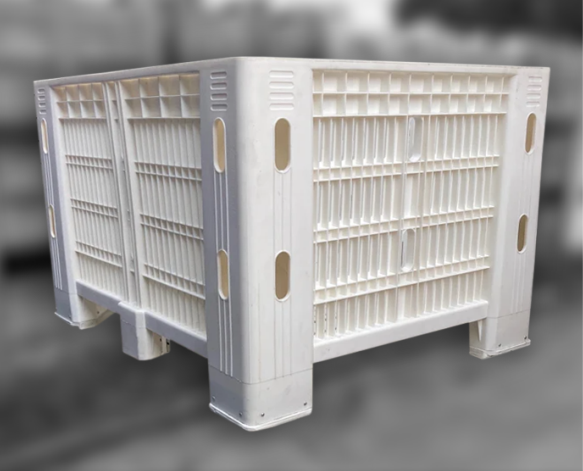

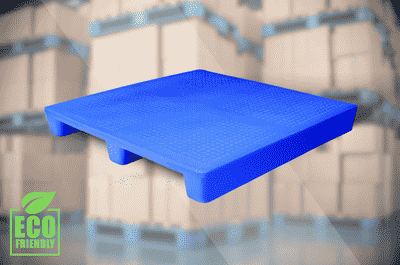

Plastic Pallets

Innovative material handling solutions for a

suitable future, providing expertise solutions

for over 17 years

suitable future, providing expertise solutions

for over 17 years

Premier plastic pallets manufacturer in India

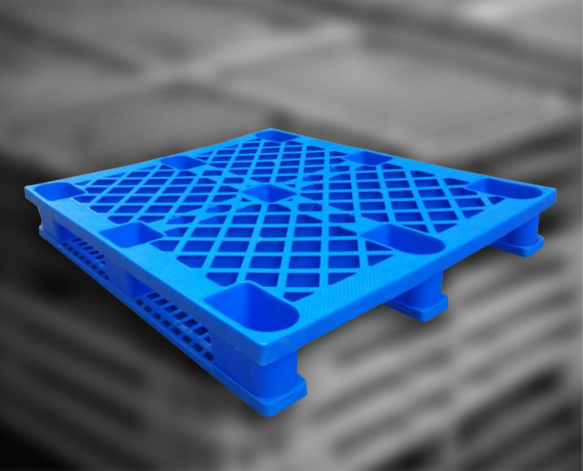

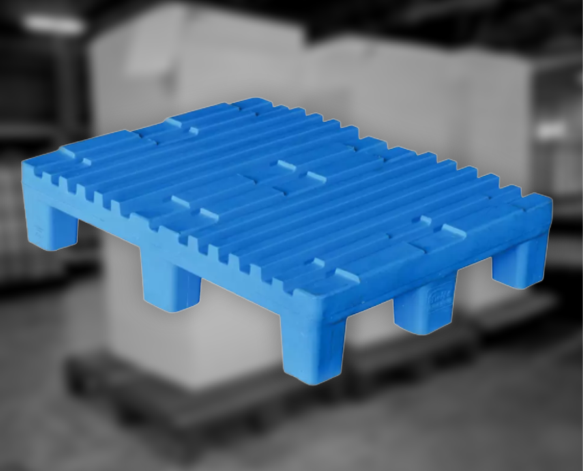

Offering Expertise

In Plastic Pallets For Industrial Segment

With over 17 years of excellence, we specialize in providing

cutting-edge plastic pallets designed

for the industrial segment.

cutting-edge plastic pallets designed

for the industrial segment.