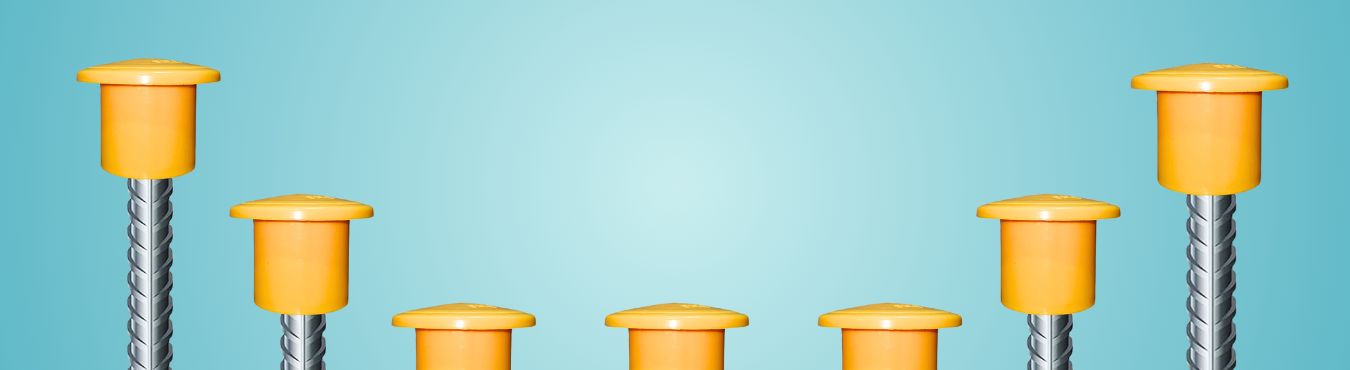

Safety is an important aspect on construction sites due to their dynamic and dangerous work environment. Rebar safety caps are an essential part of maintaining worker’s safety. These modest-looking small caps have a big impact on safety and are extremely important in preventing serious injuries or even workplace deaths.

The importance of rebar safety caps, as well as their types, advantages, and best practices for usage in construction sites, are all covered in this article.

What are Rebar Safety Caps?

Rebar safety caps are shields for the reinforcing bars (rebar) used in construction. They are also known as rebar protection caps or rebar end caps. but their exposed, pointed edges can cause harm to the workers. Rebar safety caps are intended to reduce these dangers by providing a cushion that avoids direct contact with the sharp edges.

Importance of Rebar Safety Caps

1. Preventing Injuries

The basic function of rebar safety caps is to prevent injury. Construction sites are teeming with activity, and workers frequently move rapidly and transport big objects. Coming into touch with an exposed rebar end can result in significant injuries such as impalement, wounds, and bruising. Rebar safety caps form a protective barrier, significantly reducing the risk of such incidents.

2. Enhancing Visibility

Rightly colored rebar safety caps make them easily visible on construction sites. This enhanced visibility serves as a visual cue for workers to exercise caution around areas with exposed rebar. Additionally, the bright colors help supervisors and safety inspectors quickly identify whether safety measures are in place, facilitating better site management.

Installing Rebar Safety Caps

The installation process for rebar safety caps is relatively straightforward:

- Select the Right Cap: Choose a cap that fits the rebar size and type used on your site.

- Place the Cap: Position the cap over the exposed end of the rebar. Ensure that it covers the entire end and fits snugly.

- Secure the Cap: Some caps may need securing mechanisms, such as clips or fasteners. Follow the instructions provided by the manufacturer to keep the cap in place.

Types of Rebar Safety Caps

Rebar safety caps come in various types, each designed to suit specific needs and rebar sizes. The most common types include:

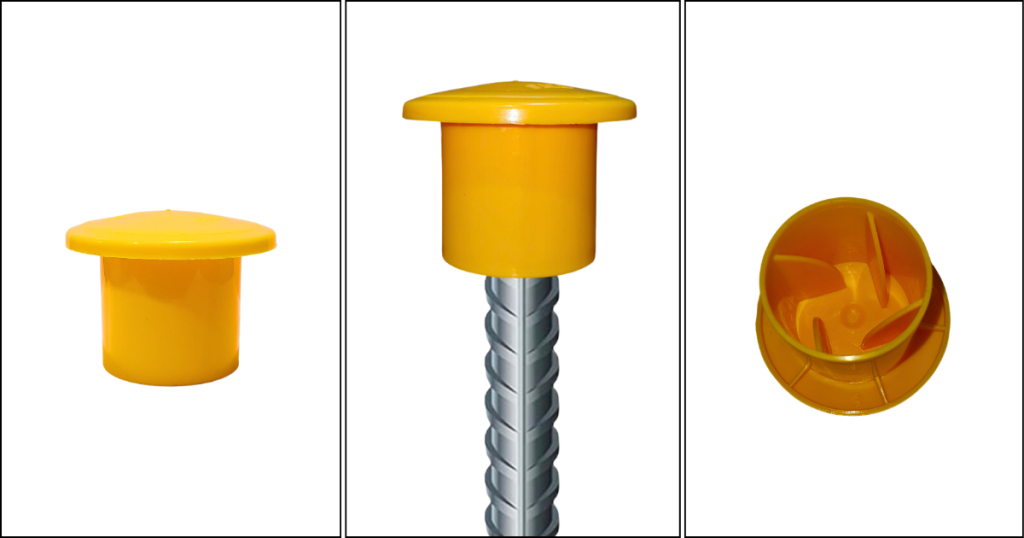

1. Mushroom Caps

Mushroom caps, often called dome caps, are the most common style of rebar safety caps. The caps feature a mushroom shape and offer a vast protective surface area. Manufacturers typically use durable plastic to make mushroom caps, engineering them to fit a wide range of rebar sizes.

2. Square Caps

Square caps are designed to fit over square-shaped rebar ends. They offer a snug fit and are ideal for projects using square rebar. These caps are made from high-quality plastic materials to withstand harsh construction conditions.

Best Practices for Using Rebar Safety Caps

To maximize the effectiveness of rebar safety caps and ensure a safe construction site, it is essential to follow the best practices:

1. Proper Installation

Check that rebar safety covers are completely fitted on all exposed rebar ends. They must fit snugly and resist easy removal. Inspect the caps regularly to ensure they stay in place during construction.

2. Regular Inspections

Regular safety inspections should be conducted to verify that all rebar ends are adequately covered with safety caps. Replace any damaged or missing caps immediately to maintain a safe working environment.

3. Training and Awareness

Provide comprehensive training to workers on the importance of rebar safety caps and how to install them correctly. Promote safety awareness, encouraging workers to report any safety concerns related to exposed rebar.

Conclusion

Rebar safety caps are vital for preventing injuries on construction sites by covering sharp rebar ends. They promote safety and increase site visibility. Construction sites can make a safer workplace by selecting the right type of cap, and properly installing it, and they should adhere to safe methods such as frequent inspections and training.

Investing in Swift’s rebar safety caps not only protects workers but also upholds safety standards and contributes to a more efficient, accident-free construction process.