Plastics are omnipresent in various aspects of our lives, from shampoo bottles to coffee mugs. Virtually everywhere, one can find them, including everyday items like seatbelt buckles. Additionally, there are many different plastic varieties due to the extraordinary array of uses for plastic. When contemplating the use of plastic pallets, understanding HDPE is crucial, as it serves as a commonly employed plastic for this purpose. Familiarity with its properties and characteristics ensures informed decision-making in selecting the right material for pallet needs.

High-Density Polyethylene, or HDPE, earns renown for its adaptability. More oversized products, such as snowboards, plastic lumber, and underground pipes, feature it due to its remarkable non-corrosive properties. It also finds applications in making milk jugs, chopping boards, and plastic bottles. Its toughness is also renowned as it can resist many conditions and settings without suffering too much damage. Since the 1950s, America has extensively made and utilized it, and it currently stands as the most popular plastic.

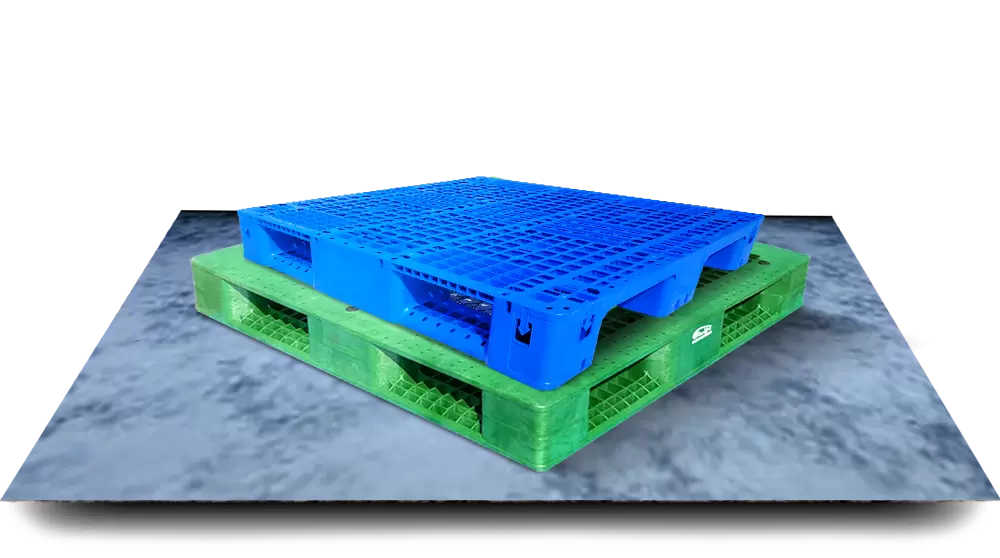

Advantages of HDPE plastic pallets

HDPE is an attractive option for plastic pallets since it has several distinctive qualities. This results from its unique chemical composition. During HDPE production, producers prevent chemical branching. Chemical bonding occurs when lengthy chains of chemical bonds develop more compact offshoots. A single molecule connects these offshoots, resembling branches, to the primary chain of molecules.Due to the lack of linking, HDPE has stronger molecular connections, increasing its strength and resistance to deformation. The production process results in producing a perfect injection-molded pellet of plastic suitable for pallets. It can handle a large amount of weight without collapsing or warping, and it can survive uncommon or harsh circumstances.

- Durability: HDPE is a polymer that is highly durable because of its chemical makeup. With no problems, it can survive challenging storage conditions, huge loads, and unusual weather conditions. This makes it perfect for plastic pallets, ensuring they remain in good condition. The plastic pallets will be prepared for the next shipment regardless of what happens during shipping. Additionally, storing pallets made of HDPE plastic is much simpler than storing pallets made of wood or less sturdy plastic. Additional, more specific advantages of durability pertain to HDPE pallets.

- Recyclable: Recycling facilities are set up to appropriately recycle and reuse HDPE because it is so standard. One of the most frequently recycled plastics is HDPE, which has a resin number of 2. HDPE pallets are an excellent choice if protecting the environment is essential to you. The advantages of products created from new HDPE are also present in those made from recycled HDPE. You might also consider these as alternatives for your pallets; on occasion, they are less expensive than pallets manufactured with completely new HDPE. Additionally, some plants might provide buyback or exchange programs that allow you to trade in your used HDPE pallets for cash or a new one in exchange.

- Lightweight: HDPE is less dense than the typical alternative to wood for pallets, despite the word “density” being right there in the name. Pallets made this way are substantially lighter, making them easier to store and transport and lowering shipping costs. Additionally, HDPE pallets can still accommodate a typical load of your product, so they do not sacrifice practicality in favor of weight.

- Easy to clean: HDPE is plastic; cleaning it up after usage only requires wiping or spraying. For your standard pallets, all you need is water, possibly some soap, and a rag. Especially useful when carrying food or medicines, as it allows for disinfecting and reusing the same pallet rather than discarding it as soon as the goods are delivered. When exporting food, you may easily adhere to FDA regulations while maintaining the use and safety of your pallets for all other types of shipment. Additionally, HPDE, resistant to decay, insects, mold, and mildew, can stay clean for many years.

- Easy to Store: These pallets can withstand any environment’s humidity since HDPE is so resilient, allowing them to be stored in any space without concern. A non-climate-controlled facility can be used, and usable pallets are maintained because moisture or air temperature does not impact them. Due to their negligible weight, plastic pallets allow for stacking much higher than wood pallets without risking injury to workers, breakage, or the possibility of the pallets falling.

- Chemical Resistant: Since HDPE is essentially non-reactive, most other compounds have little to no impact on it. As a result, HDPE pallets are perfect for moving chemicals and pharmaceutical supplies because there is no chance of a failed or broken pallet. You can use HDPE to transport the majority of substances you need. Of course, there are still some chemicals that have an impact on it, so avoid letting it come into prolonged contact with hydrocarbons or oxidizing agents. Because HDPE is a plastic, corrosive chemicals like chlorine should not expose it for prolonged periods. Instead, it is better to use other plastics for this purpose. However, if you are looking for a chemically resistant plastic that is not as durable, then HDPE might be a good choice for you. ‘ part of the current text part of the present text.

Because HDPE is a somewhat inert material, it is relatively resistant to chemicals, weather, and physical abuse. Additionally, because HDPE is essentially non-reactive, most other compounds have little to no impact on it. As a result, HDPE plastic pallets are perfect for moving chemicals and pharmaceutical supplies because there is no chance of a failed or broken pallet.

Of course, there are still some chemicals that have an impact on it, so avoid letting it come into prolonged contact with hydrocarbons or oxidizing agents. Manufacturing HDPE plastic pallets is a complicated process. First, select an appropriate plastic resin; then, melt the plastic into plastic pallets. Plastic pallets are classified into seven fractions, which different companies sell under their names. The number of plastic pallets used for pallets identifies the types of plastic pallets. HDPE plastic pallets have many benefits compared to wood. They are easier to store, lower in cost, lighter in weight, and much more environmentally friendly. HDPE plastic pallets act quickly and find utility in areas that other types of plastics cannot enter.